|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

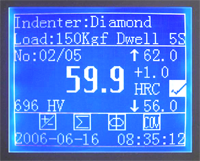

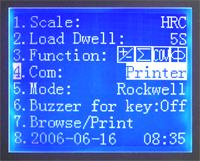

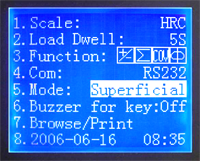

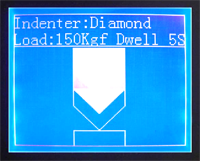

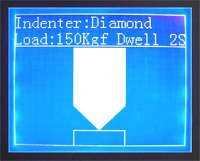

The Rockwell hardness test is one of several common indentation hardness tests used today, other examples being the Brinell hardness test and Vickers hardness test. Most indentation hardness tests are a measure of the deformation that occurs when the material under test is penetrated with a specific type of indenter . In the case of the Rockwell hardness test, two levels of force are applied to the indenter at specified rates and with specific dwell times. Unlike the Brinell and Vickers tests, where the size of the indentation is measured following the indentation process, the Rockwell hardness of the material is based on the difference in the depth of the indenter at two specific times during the testing cycle. The value of hardness is calculated using a formula that was derived to yield a number falling within an arbitrarily defined range of numbers known as a Rockwell hardness scale. The general Rockwell test procedure is the same regardless of the Rockwell scale or indenter being used. The indenter is brought into contact with the material to be tested, and a preliminary force (formally referred to as the minor load) is applied to the indenter. The preliminary force is usually held constant for a set period of time (dwell time), after which the depth of indentation is measured. After the measurement is made, an additional amount of force is applied at a set rate to increase the applied force to the total force level (formally referred to as the major load). The total force is held constant for a set time period, after which the additional force is removed, returning to the preliminary force level. After holding the preliminary force constant for a set time period, the depth of indentation is measured a second time, followed by the removal of the indenter from the test material. The measured difference between the first and second indentation depth measurements, "h", is then used to calculate the Rockwell hardness number. For many older models of Rockwell hardness machines , the operator must manually control most or all of the steps of the test procedure. Many of today's newer machines automatically perform the entire Rockwell test. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| HOME | RESOURCES | SERVICES | TRADE SHOWS | CONTACTS | LINKS Copyright © Rockwell-HardnessTesters.com |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||