|

||||||||||||||||||||||||||

MET-U1A & MET-U1A50 |

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

IP66 Waterproof and Dustproof! |

||||||||||||||||||||||||||

Non-Destructive Hardness Testing!The PHASE II ultrasonic/dynamic portable hardness testers are capable of measuring the surface hardness of a broad variety of metals on flat, round, thin or large surfaces. Unlike the standard Dynamic hardness testers, these "state-of-the-art" portable hardness testers incorporate "Ultrasonic UCI" technology, which enables the hardness testing of very thin and small workpieces, which otherwise could not be tested accurately using a portable device. Non-destructive in it's function, these hardness testers allow for the testing of highly sensitive or finished parts that previously could not be tested in an operational setting. The non-destructive (ndt) feature of these hardness testers allow the operator to accurately test parts without causing physical or structural damage that would normally lead to disposal or refinish of operators part. That translates into less scrap parts/ lower mfg costs due to necessary inspections. PHASE II offers two models of ultrasonic hardness testers that are capable of measuring the surface hardness of a broad variety of metals on flat, round, thin or large surfaces. Accurate measurements of steel, cast steel, alloy steel, aluminum, brass, bronze and copper are easily attained with this compact instrument. The MET-U1A/U1A50 meets ASTM A1038-10 specifications. |

||||||||||||||||||||||||||

UCI Portable Hardness Testing Method: |

||||||||||||||||||||||||||

Pre-Programmed Scales/Material: Others combinations can be added upon request

|

||||||||||||||||||||||||||

MET-U1A & MET-U1A50 Hardness Tester Standard Accessories:

Functions:

Specifications:

|

||||||||||||||||||||||||||

Technical data for MET U1A/U1A50

|

||||||||||||||||||||||||||

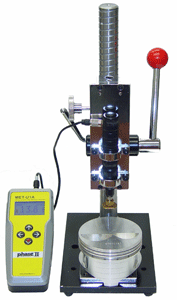

Shown with Optional Support Stand |

||||||||||||||||||||||||||

| HOME | RESOURCES | SERVICES | TRADE SHOWS | CONTACTS | LINKS Copyright © Rockwell-HardnessTesters.com |

||||||||||||||||||||||||||